The Fukushima Daiichi nuclear disaster (福島第一原子力発電所事故 Fukushima Dai-ichi ( pronunciation) genshiryoku hatsudensho jiko) is a series of equipment failures, nuclear meltdowns, and releases of radioactive materials at the Fukushima I Nuclear Power Plant, following the Tōhoku earthquake and tsunami on 11 March 2011.[5][6] It is the largest nuclear disaster since the Chernobyl disaster of 1986.[7]

pronunciation) genshiryoku hatsudensho jiko) is a series of equipment failures, nuclear meltdowns, and releases of radioactive materials at the Fukushima I Nuclear Power Plant, following the Tōhoku earthquake and tsunami on 11 March 2011.[5][6] It is the largest nuclear disaster since the Chernobyl disaster of 1986.[7]

The plant comprises six separate boiling water reactors originally designed by General Electric (GE), and maintained by theTokyo Electric Power Company (TEPCO). At the time of the quake, Reactor 4 had been de-fuelled while 5 and 6 were in coldshutdown for planned maintenance.[8] The remaining reactors shut down automatically after the earthquake, and emergency generators came online to control electronics and coolant systems. The tsunami broke the reactors' connection to the power grid and also resulted in flooding of the rooms containing the emergency generators. Consequently those generators ceased working and the pumps that circulate coolant water in the reactor ceased to work, causing the reactors to begin to overheat. The flooding and earthquake damage hindered external assistance.

In the hours and days that followed, reactors 1, 2 and 3 experienced full meltdown.[9][10] As workers struggled to cool and shut down the reactors, several hydrogen explosions occurred.[11] The government ordered that seawater be used to attempt to cool the reactors—this had the effect of ruining the reactors entirely.[12] As the water levels in the fuel rods pools dropped, they began to overheat. Fears of radioactivity releases led to a 20 km (12 mi)-radius evacuation around the plant. During the early days of the accident workers were temporarily evacuated at various times for radiation safety reasons. Electrical power was slowly restored for some of the reactors, allowing for automated cooling.[13]

Japanese officials initially assessed the accident as Level 4 on the International Nuclear Event Scale (INES) despite the views of other international agencies that it should be higher. The level was successively raised to 5 and eventually to 7, the maximum scale value.[14][15] The Japanese government and TEPCO have been criticized in the foreign press for poor communication with the public and improvised cleanup efforts.[16][17][18] On 20 March, the Chief Cabinet Secretary Yukio Edano announced that the plant would be decommissioned once the crisis was over.

The Japanese government estimates the total amount of radioactivity released into the atmosphere was approximately one-tenth as much as was released during the Chernobyl disaster.[19] Significant amounts of radioactive material have also been released into ground and ocean waters. Measurements taken by the Japanese government 30–50 km from the plant showed caesium-137levels high enough to cause concern,[20] leading the government to ban the sale of food grown in the area. Tokyo officials temporarily recommended that tap water should not be used to prepare food for infants.[21][22]

On 24 May 2012, more than a year after the disaster, TEPCO released their estimate of radioactive material emitted due to the Fukushima Daiichi Nuclear Disaster.[23] An estimated 538.1 PBq of non noble gas radionuclides iodine-131, caesium-134 and caesium-137 was released. This 520 PBq of radioactive material was released into the atmosphere between 12 March to 31 March 2011 and 18.1 PBq into the ocean from 26 March to 30 September 2011. This represents 10% of the 5300 PBq of non noble gas radionuclides released in the 1986 Chernobyl disaster.[24] A total of 511 PBq of iodine-131 was released into both the atmosphere and the ocean, 13.5 PBq of caesium-134 and 13.6 PBq of caesium-137.

In May 2012, TEPCO reported that at least 900 PBq had been released "into the atmosphere in March last year [2011] alone".[25][26]

A few of the plant's workers were severely injured or killed by the disaster conditions resulting from the earthquake. There were no immediate deaths due to direct radiation exposures, but at least six workers have exceeded lifetime legal limits for radiation and more than 300 have received significant radiation doses. Predicted future cancer deaths due to accumulated radiation exposures in the population living near Fukushima have ranged from none[27] to 100[28] to a non-peer-reviewed "guesstimate"[29] of 1,000.[19]Fear of ionizing radiation could have long-term psychological effects on a large portion of the population in the contaminated areas. On 16 December 2011 Japanese authorities declared the plant to be stable, although it would take decades to decontaminate the

Fukushima I Nuclear Power Plant

Main article: Fukushima I Nuclear Power Plant

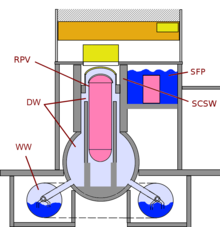

The Fukushima I Nuclear Power Plant consists of six light water, boiling water reactors (BWR) designed by General Electric driving electrical generators with a combined power of 4.7 gigawatts, making Fukushima I one of the 25 largest nuclear power stations in the world. Fukushima I was the first GE designed nuclear plant to be constructed and run entirely by the Tokyo Electric Power Company(TEPCO).

Unit 1 is a 439 MWe type (BWR3) reactor constructed in July 1967. It commenced commercial electrical production on 26 March 1971.[31] It was designed for a peak ground acceleration of 0.18 g (1.74 m/s2) and a response spectrum based on the 1952 Kern County earthquake.[32] Units 2 and 3 are both 784 MWe type BWR-4 reactors, Unit 2 commenced operating in July 1974 and Unit 3 in March 1976. The earthquake design basis for all units ranged from 0.42 g (4.12 m/s2) to 0.46 g (4.52 m/s2).[33][34] All units were inspected after the 1978 Miyagi earthquake when the ground acceleration was 0.125 g (1.22 m/s2) for 30 seconds, but no damage to the critical parts of the reactor was discovered.[32]

Units 1–5 have a Mark 1 type (light bulb torus) containment structure, Unit 6 has Mark 2 type (over/under) containment structure.[32]From September 2010, Unit 3 has been partially fuelled by mixed-oxide (MOX) fuel.[35]

At the time of the accident, the units and central storage facility contained the following numbers of fuel assemblies:[36]

Location Unit 1 Unit 2 Unit 3 Unit 4 Unit 5 Unit 6 Central Storage Reactor Fuel Assemblies 400 548 548 0 548 764 0 Spent Fuel Assemblies 292 587 514 1331 946 876 6375 Fuel UOx UOx UO2/MOX UOx UOx UOx UO2/MOX New Fuel Assemblies[37] 100 28 52 204 48 64 N/A

[edit]Cooling requirements

Power reactors work by splitting atoms, typically uranium, in a chain reaction. The reactor continues to generate heat after the chain reaction is stopped because of the radioactive decay of unstable isotopes, fission products, created by this process. This decay of unstable isotopes, and the decay heat, cannot be stopped.[38][39] Immediately after shutdown, this decay heat amounts to approximately 6% of full thermal heat production of the reactor.[38] The decay heat in the reactor core decreases over several days before reaching cold shutdown levels.[40] Nuclear fuel rods that have reached cold shutdown temperatures typically require another several years of water cooling in a spent fuel pool before decay heat production reduces to the point that they can be safely transferred to dry storage casks.[41]

To safely remove this decay heat, reactor operators must continue to circulate cooling water over fuel rods in the reactor core and spent fuel pond.[38][42] In the reactor core, circulation is accomplished by use of high pressure systems that pump water through the reactor pressure vessel and into heat exchangers. These systems transfer heat to a secondary heat exchanger via the essential service water system, taking away the heat which is pumped out to the sea or site cooling towers.[43]

To circulate cooling water when the reactor is shut down and not producing electricity, cooling pumps can be powered by other units on-site, by other units off-site through the grid, or by diesel generators.[42][44] In addition, boiling water reactors have steam-turbine driven emergency core cooling systems that can be directly operated by steam still being produced after a reactor shutdown, which can inject water directly into the reactor.[45] Steam turbines results in less dependence on emergency generators, but steam turbines only operate so long as the reactor is producing steam. Some electrical power, provided by batteries, is needed to operate the valves and monitoring systems.

If the water in the Unit 4 spent fuel pool had been heated to boiling temperature, the decay heat has the capacity to boil off about 70 tonnes of water per day (12 gallons per minute), which puts the requirement for cooling water in context.[46] On 16 April 2011, TEPCO declared that Reactors 1–4's cooling systems were beyond repair and would have to be replaced.[47]

The reason that cooling is so essential for a nuclear reactor, is that many of the internal components and fuel assembly cladding is made from zircaloy. At normal operating temperatures (of approximately 300 degrees Celsius), zircaloy is inert. When heated to above 500 degrees Celsius in the presence of steam,[48] zircaloy undergoes an exothermicreaction where the zircaloy oxidises and produces hydrogen. The reaction between the zirconium cladding and the fuel can lower the melting point of the fuel and thus speed up a core melt.[49]

The reactor's emergency diesel generators and DC batteries, crucial components in powering the reactors' cooling systems in the event of a power loss, were located in the basements of the reactor turbine buildings. The reactor design plans provided by General Electric specified placing the generators and batteries in that location, but mid-level engineers working on the construction of the plant were concerned that this made the back-up power systems vulnerable to flooding. TEPCO elected to strictly follow General Electric's design in the construction of the reactors.[50]

[edit]Safety history

[edit]1967: Changing the layout of the emergency-cooling system, without reporting it

On 27 February 2012 NISA ordered TEPCO to report by 12 March 2012 about the reasoning to change the layout for the piping for an emergency cooling system from the plans originally registered in 1966 before the reactor was taken in operation.

After the plant was hit by the tsunami, the isolation condenser should have taken over the function of the ordinary cooling pumps, by condensing the steam from the pressure vessel into water to be used for cooling the reactor. But the condenser did not function properly, and TEPCO could not confirm whether a valve was opened.

In the original papers submitted – in July 1966 – for government approval of the plans to set up the reactor, the piping systems for two units in the isolation condenser were separated from each other. But in the application for the construction plan of the reactor – submitted in October 1967 – the piping layout was changed by TEPCO, and the two piping systems were connected outside the reactor. The changes were not reported in violation of all legal regulations.[51]

[edit]1976: Falsification of safety records by TEPCO

The Fukushima Daiichi nuclear power complex was central to a falsified-records scandal that led to the departure of a number of senior executives of TEPCO. It also led to disclosures of previously unreported problems at the plant,[52] although testimony by Dale Bridenbaugh, a lead GE designer, purports that General Electric was warned of major design flaws in 1976, resulting in the resignations of several designers who protested GE's negligence.[53][54][55]

In 2002, TEPCO admitted it had falsified safety records at the No. 1 reactor at Fukushima Daiichi. As a result of the scandal and a fuel leak at Fukushima Daini, the company had to shut down all of its 17 nuclear reactors to take responsibility.[56] A power board distributing electricity to a reactor's temperature control valves was not examined for 11 years. Inspections did not cover devices related to cooling systems, such as water pump motors and diesel generators.[57]

[edit]1991: Back-up generator of reactor nr. 1 flooded

On 30 October 1991 one of two backup generators of reactor nr. 1 did fail, after it was flooded in the basement of the reactor buildings. Seawater used for the cooling of the reactor was leaking into the turbine-building from a corroded pipe at a rate of 20 cubic meters per hour. This was told by former TEPCO employees to the Japan Broadcasting Corporationnews-service in December 2011. An engineer told, that he informed his superiors about this accident, and that he mentioned the possibility that a tsunami could inflict damage to the generators in the turbine-buildings near the sea. After this TEPCO did not move the generators to higher grounds, but instead TEPCO installed doors to prevent water leaking into the generator rooms. The Japanese Nuclear Safety Commission commented that it would revise the safety guidelines for designing nuclear plants and would enforce the installation of additional power sources. On 29 December 2011 TEPCO admitted all these facts: its report mentioned, that the emergency power system room was flooded through a door and some holes for cables, but the power supply to the reactor was not cut off by the flooding, and the reactor was stopped for one day. One of the two power sources was completely submerged, but its drive mechanism had remained unaffected.[58][59][60]

[edit]2006: The Japanese government opposes a court-order

In March 2006 the Japanese government opposed a court order to close a nuclear plant in the west part of the country over doubts about its ability to withstand an earthquake. Japan's Nuclear and Industrial Safety Agency believed it was "safe" and that "all safety analyses were appropriately conducted".[61]

[edit]2007: Tsunami-study ignored

In 2007 TEPCO did set up a department to supervise all its nuclear facilities, and until June 2011 its chairman was Masao Yoshida, the chief of the Fukushima Daiichi power plant. An in-house study in 2008 pointed out that there was an immediate need to improve the protection of the power station from flooding by seawater. This study mentioned the possibility of tsunami-waves up to 10.2 meters. Officials of the department at the company's headquarters insisted that such a risk was unrealistic and did not take the prediction seriously.[62]

[edit]2008: Seismic-concerns

In addition to concerns from within Japan, the International Atomic Energy Agency (IAEA) has also expressed concern about the ability of Japan's nuclear plants to withstand seismic activity. At a meeting of the G8's Nuclear Safety and Security Group, held in Tokyo in 2008, an IAEA expert warned that a strong earthquake with a magnitude above 7.0could pose a "serious problem" for Japan's nuclear power stations.[63]

[edit]2011: Results of Governmental Investigations

On request of the Japan Broadcasting Corporation, on 2 October 2011 the Japanese Government released a report of TEPCO to NISA. These papers proved that TEPCO was well aware of the possibility that the plant could be hit by a tsunami with waves far higher than the 5.7 meters which the plant was designed to withstand. Simulations done in 2008, based on the destruction caused by the 1896-earthquake in this area, made it clear that waves between 8.4 and 10.2 meters could overflow the plant. Three years later the report was sent to NISA, where it arrived on the 7 March 2011, just 4 days before the plant was hit by the tsunami. Further studies by scientists and an examination of the plant's tsunami resistance measures were not planned by TEPCO before April 2011, and no further actions were planned to deal with this subject before October 2012. TEPCO official Junichi Matsumoto said that the company did not feel the need to take prompt action on the estimates, which were still tentative calculations in the research stage. An official of NISA said that these results should have been made public by TEPCO, and that the firm should have taken measures right away.[64][65]

This all was in sharp contrast with the events at the Tōkai Nuclear Power Plant where the dike around the plant was raised to 6.1 meters after evaluations showed the possibility of tsunami-waves higher than previously expected. Although the dike was not completely finished at 11 March 2011, the plant could ride out the tsunami, even though the external power-sources in Tokai were lost too. With two (of three) functioning sea-water-pumps and the emergency diesel-generator the reactor could be kept safely in cold shutdown.[66]

On 26 November a TEPCO spokesman mentioned that TEPCO would have been better prepared to cope with the tsunami in March 2011, if it had taken the 2008-study more seriously. TEPCO was also willing to use the estimates of renewed study done by a national civil engineering society for its facility management.[62]

Nuclear Safety Commission Chairman Haruki Madarame told a parliamentary inquiry in February 2012 that "Japan's atomic safety rules are inferior to global standards and left the country unprepared for the Fukushima nuclear disaster last March". There were flaws in, and lax enforcement of, the safety rules governing Japanese nuclear power companies, and this included insufficient protection against tsunamis.[67]

[edit]After the tsunami

Further information: Timeline of the Fukushima I nuclear accidents and 2011 Tōhoku earthquake and tsunami

The 9.0 MW Tōhoku earthquake occurred at 14:46 JST on Friday, 11 March 2011 with epicenter near the island of Honshu.[68] It resulted in maximum ground accelerations of 0.56, 0.52, 0.56 g (5.50, 5.07 and 5.48 m/s2) at Units 2, 3 and 5 respectively, above their designed tolerances of 0.45, 0.45 and 0.46 g (4.38, 4.41 and 4.52 m/s2), but values within the design tolerances at Units 1, 4 and 6.[34] The Fukushima I facility had not initially been designed for a tsunami of the size that struck the plant,[69][70] nor had the reactors been modified when later concerns were raised in Japan and by the IAEA.[71] When the earthquake occurred, the reactors on Units 1, 2, and 3 were operating, but those on Units 4, 5, and 6 had already been shut down for periodic inspection.[33][72] Units 1, 2 and 3 underwent an automatic shutdown (called SCRAM) when the earthquake struck.[73][74]

When the reactors shut down, the plant stopped generating electricity, stopping the normal source of power for the plant.[75] TEPCO reported that one of the two connections to off-site power for Reactors 1–3 also failed[75] so 13 on-site emergency diesel generators began powering the plant's cooling and control systems.[76] There are two emergency diesel generators for each of the Units 1–5 and three for Unit 6.[77]

The earthquake was followed by a 13–15 m (43–49 ft) maximum height tsunami arriving approximately 50 minutes later which topped the plant's 5.7 m (19 ft) seawall,[78][79][80] flooding the basement of the Turbine Buildings and disabling the emergency diesel generators[81][82] located there[77] at approximately 15:41.[75][83] At this point, TEPCO notified authorities, as required by law, of a "First level emergency".[73] The Fukushima II plant, which was also struck by the tsunami, incorporated design changes which improved its resistance to flooding and it sustained less damage. Generators and related electrical distribution equipment were located in the watertight reactor building, so that power from the grid was being used by midnight.[84] Seawater pumps for cooling were given protection from flooding, and although 3 of 4 failed in the tsunami, they were able to be restored to operation.[85]

In the late 1990s, three additional backup generators for reactors Nos. 2 and 4 were placed in new buildings located higher on the hillside, to comply with new regulatory requirements. All six reactors were given access to these generators, but the switching stations that sent power from these backup generators to the reactors' cooling systems for Units 1 through 5 were still in the poorly protected turbine buildings. All three of the generators added in the late 1990s were operational after the tsunami. If the switching stations had been moved to inside the reactor buildings or to other flood-proof locations, power would have been provided by these generators to the reactors' cooling systems.[86]

After the diesel generators located in the turbine buildings failed, emergency power for control systems was supplied by batteries that were designed to last about eight hours.[87]Further batteries and mobile generators were dispatched to the site, delayed by poor road conditions with the first not arriving until 21:00 JST 11 March,[76][88] almost six hours after the tsunami struck.

Attempts to connect portable generating equipment to power water pumps were eventually discontinued after numerous attempts, as the connection point in the Turbine Hall basement was flooded and because of difficulties finding suitable cables.[81] TEPCO switched its efforts to installing new lines from the grid to the cooling systems.[89] One plant generator at Unit 6 was restored to operation on 17 March, and external power returned to Units 5 and 6, on 20 March, allowing cooling equipment to be restarted.[90]

I am very interested in the article that you wrote ... really quite remarkable

ReplyDelete